AirTAC aligns with the global trends of sustainability, green products and fulfills its environmental responsibility as a manufacturer. Centered on clean technology, the Company continues to invest in R&D resources to develop a diverse range of products.

Sustainable products

AirTAC aligns with the global trends of sustainability and green products and fulfills its environmental responsibility as a manufacturer. Centered on clean technology, the company continues to invest in R&D resources to develop a diverse range of products.

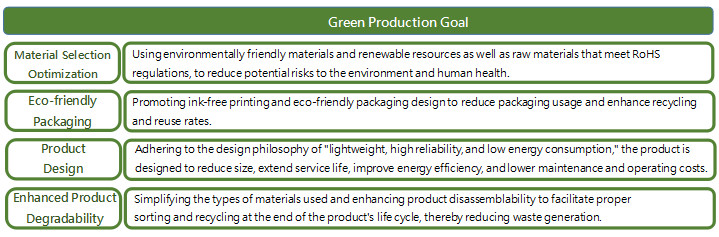

With environmentally friendly products as our goal, we strive to incorporate environmental principles throughout every stage of our operations. From product development to the selection of raw materials, we prioritize energy efficiency, choosing low-carbon materials, introducing new equipment, and optimizing manufacturing processes to reduce energy consumption, carbon emissions, and pollutant generation across the product lifecycle. Furthermore, we emphasize reducing, reusing, recycling, and re-purposing packaging materials, with priority given to minimizing packaging volume.

Management Policies

The Company has embraced low-carbon transformation as a core corporate value. It incorporates the concepts of low-carbon and green transformation throughout the entire product lifecycle, including raw material procurement, research and development, production, manufacturing, product sales, and distribution processes. AirTAC comprehensively advances the sustainable commitment to "energy conservation, consumption reduction, clean production, and green manufacturing."

|

Life Cycle |

Management Policies |

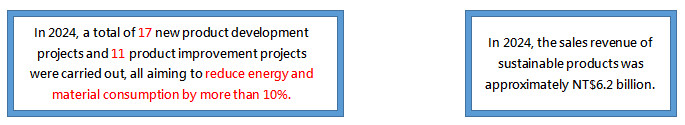

2024 Actual Performance |

|

R&D Resources |

Continue to increase investment in innovation and R&D, and plans to link product financial performance with the R&D budget. |

R&D expenditure in 2024 amounted to NT$1.04 billion, accounting for 4% of revenue. |

|

Raw Material Development |

● No harmful raw materials are used, and all raw materials for production comply with ROHS standards.

● Low-carbon emission raw materials are used. |

● In 2024, the proportion of renewable raw materials used was approximately 43%.

● The primary raw materials used in production are 100% compliant with RoHS requirements and 100% free of conflict minerals. |

|

Production |

● By optimizing processes, products are made lighter to reduce the use of raw materials.

● Through the introduction of new equipment and process optimization, energy consumption is reduced. |

● Through process improvements, the ACT cylinder has been light weighted, saving approximately 208 tons of aluminum annually and reducing around 7,939 tons of CO2e emissions.

● By reducing the thickness of the aluminum tube in the standard cylinder, approximately 152 tons of aluminum are saved annually, resulting in a reduction of about 5,801 tons of CO2e emissions each year. |

|

Transportation |

● Optimize delivery methods, routes, and fleet vehicles to reduce fuel consumption generated during transportation.

● Use recyclable green packaging materials and modify packaging methods to decrease the amount of packaging used. |

● To enhance transportation efficiency and achieve carbon reduction goals, AirTAC outsourced most of its cargo logistics operations to a professional logistics company starting in July 2023. Through systematic delivery planning and the integration of transportation resources, optimized routes can be precisely arranged to improve loading efficiency, significantly reduce the number of under loaded trips by in-house vehicles, and thereby effectively lower overall fuel consumption and carbon emissions, achieving energy conservation and carbon reduction in the transportation process.

● In 2024, AirTAC China replaced 69 old gasoline vehicles with new energy-efficient vehicles. In 2025, the Company plans to phase out 109 gasoline vehicles and purchase 100 hybrid vehicles. |

|

Product Usage |

By optimizing the processes, we enhance product efficiency, which in turn reduces energy consumption. |

● The JSK series welding clamp cylinder has been light weighted, reducing air consumption by 17%. Over the product life cycle, this improvement is expected to save approximately 2.56 million kWh of electricity, equivalent to reducing about 1,388 tons of CO2e emissions.

● By reducing the use of enameled coil wire in the 4V solenoid valve, power consumption was lowered. Over the product life cycle, this improvement is expected to save approximately 9.34 million kWh of electricity, equivalent to reducing about 5,065 tons of CO2e emissions. |

|

Disposal or Recycling |

Continuously promote waste classification and reduction, increasing the proportion of waste recycling and reuse. |

The recycling and reuse rate of waste for the year 2024 is 95%. |