AirTAC complies with occupational safety and health regulations in all locations where it operates. Guided by the corporate values of people oriented, profit sharing, common development, and undertaking responsibilities, the Company aims to create the best possible safe and healthy workplace and to pursue a sustainable future. To prevent workplace accidents, provide a friendly working environment, and protect the safety of employees and contractors, the Company has implemented an occupational safety and health management system.

Occupational Safety and Health Strategies and Targets

Targets

1. Create a safe workplace, promote environmental protection and promote the concept of safety and health.

2. Encourage everyone to comply with the policy, implement pollution prevention, and effectively manage the risks of safety and environmental.

3. Promote physical and mental well-being, raise awareness of environmental safety, and mental health to make Work-Life Balance.

Strategies

1. Comply with laws and regulations, and strengthen a safe and friendly working environment.

2. Identify opportunities and risks, prevent hazards, and minimize potential impacts.

3. Integrate environmental and safety education, and encourage proactive consultation and communication.

4. Reuse resources and implement ecosystem protection.

5. Continuously improve and advance practices to develop a sustainable and healthy workplace.

Occupational Safety and Health Management System

AirTAC Taiwan has been certified under ISO 45001 (Occupational Health and Safety Management Systems) with a certificate valid from January 4, 2024, to January 3, 2027, and AirTAC Ningbo has held a Level 2 Enterprise Certificate for Safety Production Standardization since 2017. AirTAC's occupational health and safety management systems across all plants continue to operate effectively. Through education, awareness campaigns, and drills, all stakeholders are clearly informed of their respective safety and health responsibilities and rights, thereby reducing or eliminating associated risks and impacts.

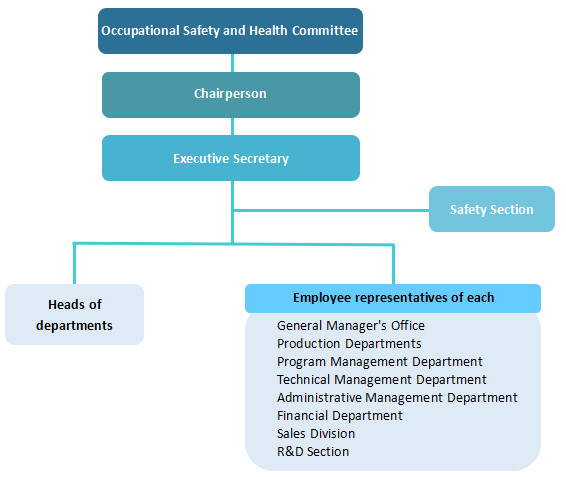

Occupational Safety and Health Committee

Note: Taking AirTAC Taiwan as an example

At all AirTAC plants, the OSH Committee provides communication channels to facilitate dialogue, consultation, and grievance handling. In addition to including management members responsible for decision-making and employee representatives, the Committee also offers a platform for employees to participate in the occupational safety and health management system. Employees can share ideas or suggestions, which are consolidated by departmental representatives and communicated through the Committee to senior management.

Occupational Safety and Health Measures

AirTAC adopts the following measures and procedures to prevent hazards and to ensure the health and safety of our employees.

|

Hazard Identification |

Regular environmental hazards risk assessments to assess whether the operating procedures comply with regulations.

The Company requires corrections for non-compliant procedures in accordance with legal requirements and tracks improvement through internal regulations. |

|

Communication and Engagement |

Occupational Safety and Health Committee

Internal communication, consultation, and complaint procedures |

|

Health Protection |

An annual health examination with specific items is arranged for employees in special operation positions (such as those exposed to high noise levels, dust, etc.).

Routine workplace environment monitoring is conducted twice a year.

On-site medical rooms, doctor visits. |

|

Training and Education |

Safety and health training programs are provided for new employees and current staff.

Special hazard or first-aid training is conducted three times a year in accordance with the needs of specific operations.

A regular annual training is conducted for officers of the Occupational Health and Safety Management System.

Ensuring the health of on-site factory doctors and nurses. |

|

Emergency Response |

Four annual escape and evacuation simulation drills (e.g., earthquake and fire disasters) are conducted.

An annual training session on emergency first aid and responders training is conducted. |

|

Protection measures |

Relevant procedures for specific operators (such as those handling chemicals or working in high-noise environments) and formulation of corresponding control plans or measures according to risk assessment.

Continuous improvement of occupational safety and health management systems

Require the use of personal protection equipment |

|

Contractor Management |

Contractors entering the facility are required to sign a safety agreement and provide proof of occupational safety training prior to entry. In addition, they must submit all required entry documents before commencing work. Only after these documents have been reviewed and approved are contractors permitted to enter the facility for construction or operations. |

|

Internal audit |

Regular internal audits at least once a year for timely improvement measures against non-conformities; audit reports provided to relevant management units.

In cases involving personnel-related deficiencies, hazard identification and elimination processes are implemented, alongside strengthened awareness campaigns and training programs |

Note: Taking AirTAC Taiwan as an example

Occupational Safety and Health Training Courses

To ensure employees fully understand occupational safety and health (OSH) regulations and the operation of the OSH management system, and possess the necessary knowledge to respond appropriately in the event of hazards, annual audits are conducted with on-site inspections and verification activities. All employees are required to complete general orientation training upon joining the Company. In addition, employees in specific positions receive corresponding advanced professional training.

|

2024 Occupational Safety and Health Training Courses (include contract personnel) |

|

Company |

Training Course |

Number of Trainees |

Number of Training Hours |

|

AirTAC Taiwan |

Pre-employment safety education for new employees |

18 |

108 |

|

In-service education and training on occupational safety and health |

1,660 |

2,507 |

|

Occupational Safety and Health-related certifications |

60 |

320 |

|

AirTAC Ningbo |

Pre-employment safety education for new employees |

1,375 |

33,000 |

|

Safety training for on-job transfers |

378 |

6,048 |

|

Safety training for supervisors |

324 |

1,296 |

|

Training for forklift truck operators |

32 |

768 |

|

Training for safety management personnel |

13 |

176 |

|

Annual safety training for in-service employees |

4,886 |

4,886 |

|

AirTAC Guangdong |

Pre-employment safety education for new employees |

74 |

588 |

|

Training for safety management personnel |

20 |

240 |

|

Chinese New Year Return to Work Safety Training |

651 |

1,302 |

|

Dust Explosion Safety Training |

22 |

22 |

|

Total |

9,513 |

51,261 |

|

Note: AirTAC China is a sales company and has not held occupational safety and health training courses |

Hazardous Substance Management

Hazardous chemicals used in the plant's production processes are managed by professionally trained and qualified personnel. Comprehensive control measures are implemented for the procurement, dispensing, storage, and use of hazardous chemicals. Annual occupational safety and health training programs are conducted to provide employees with operational training, emergency response procedures, and relevant knowledge. Safety Data Sheets (SDS) are placed in clearly visible locations to ensure that personnel can promptly access the information needed for effective response in the event of an emergency.

Workplace Hazard Identification and Risk Assessment

Trained and qualified personnel are responsible for conducting hazard identification, using quantitative risk factors as the basis for risk assessment. After review by the occupational safety and health management unit, risk levels are established and operational control measures and improvement targets are set for identified hazards. These are incorporated into the occupational safety management system for regular monitoring to continually eliminate potential occupational hazards in the workplace. During any operation, if an immediate and dangerous emergency occurs, employees may, based on the severity of the hazard, decide to stop work or take necessary protective measures and evacuate their work areas. No adverse consequences or disciplinary actions will result from doing so.