AirTAC places great importance on the sustainable development of its industry value chain and continues to advance a sustainable supply chain management system. Environmental and social factors are incorporated into supplier contracts, and suppliers are required to strictly comply with local environmental regulations.

In accordance with the internal "RoHS 2.0 Monitoring Operations Procedures," the Quality Control Department formulates the annual inspection plan for production raw materials and the annual supplier submission plan. The Procurement Department is responsible for communicating AirTAC's Green Procurement Declaration to raw material suppliers and obtaining their inspection reports, ensuring their compliance with RoHS requirements. The Production Department cooperates in implementing related tasks, while the R&D unit is responsible for monitoring finished products.

Supplier Management

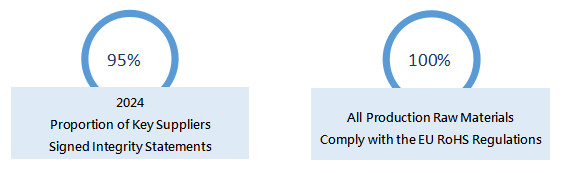

AirTAC's supplier management process includes identifying key suppliers and conducting quarterly on-site or document-based audits, while other suppliers are evaluated once a year. Evaluation criteria include delivery performance, quality, pricing, cooperation, and the handling of customer complaints. These assessments help ensure that suppliers can consistently provide high-quality and reasonably priced products and services, while also allowing AirTAC to understand their operational status and quality management mechanisms. All production raw materials comply with EU RoHS regulations.

On-site audits also cover environmental aspects, including whether suppliers have clear quality and environmental policies, whether personnel in special positions receive appropriate training, whether hazardous chemicals are properly labeled and effectively controlled, and whether the prohibition of environmentally harmful substances is clearly specified.

Status of New Supplier Contracting and Screening

To foster a shared awareness of sustainability with our business partners, AirTAC conducts both on-site and document-based audits for newly engaged suppliers. These reviews examine governance practices such as whether the supplier has obtained ISO 14001 environmental certification, ISO 45001 occupational health and safety certification, the status of hazardous substance (RoHS) control, and whether employee training is provided. This process ensures that suppliers meet AirTAC's fundamental sustainability requirements before entering the supply chain.

Supplier Classification System

To effectively manage its suppliers, AirTAC classifies them into categories to maintain a comprehensive understanding of the overall supply chain. The supply chain is currently divided into six major categories based on procurement types: raw materials, parts, auxiliary materials, equipment, outsourcing, and general and miscellaneous items.

|

Category |

Raw Materials |

Parts |

Auxiliary Materials |

Equipment |

Outsourcing |

General Miscellaneous |

|

Description |

The main or key components that make up the final product (including raw materials such as aluminum/ copper/iron/steel) |

Materials that have auxiliary functions and constitute the general part of the final product (including screws/nuts stamped parts/packaging materials/glue /oil) |

Substances that are not directly used in the product but have auxiliary functions (Packaging materials, oils, knives, etc.) |

Machinery and equipment, office equipment and information equipment, etc. |

Outsourcing surface treatment, processing supplies, etc. |

Administrative supplies |

Supplier Evaluation

AirTAC conducts annual supplier evaluations based on delivery performance, quality, pricing, cooperation, and the handling of customer complaints. Evaluation results are categorized into four levels—A, B, C, and D. Suppliers rated at level D are required to implement improvements within a specified timeframe, during which relevant training and support will be provided. If the supplier fails to make the required improvements, the cooperation will be discontinued.

Conflict Minerals Management

AirTAC's purchased raw materials and manufactured products do not contain minerals such as gold (Au), tantalum (Ta), tungsten (W), or tin (Sn). The Company does not use any minerals originating from conflict-affected regions, particularly the Democratic Republic of the Congo and its neighboring countries.